With increasingly stringent environmental legislation and pollution control standard, the demand for steel enterprises to adapt those policies is also rising. Meanwhile, steelmaking and ironmaking byproducts such as dedusting ash, mill scale, iron-containing sludge, coke fines and iron ore slag generated during steel production possess significant recycling value. Whether from the perspective of rational utilization of resource or environmental protection to eliminate dust and solid waste pollution, fully utilizing various dust and solid waste has become an indispensable part of modern steel production.

What are Cold Pressed Briquettes?

Dust, scale, sludge, coke fines, and other materials, it will lead to resource waste and environmental pollution if directly discarded. To recycle these resources, many enterprises choose to mix these waste materials with suitable binders, add water for uniform mixing and then cold press them into green balls with a diameter of 50–60 mm. These balls are then dried to achieve sufficient strength for reuse in steel and iron making. The cold pressed briquette process is simple, has a short flow, requires low investment and energy consumption and is widely adopted. Additionally, it does not require new processes or equipment for drying, nor does it occupy excessive space or time.

Definition of Cold Pressed Briquettes

Cold pressed briquettes use raw materials such as dust, scale, iron-containing sludge and coke fines, combined with binders. They are formed through a cold pressing and curing process, involving mixing, molding and drying to produce metallurgical briquettes.

Raw Materials Used in Cold Briquetting

Dust (e.g., blast furnace dust, converter dust, converter sludge), coke fines, scale, iron-containing sludge, iron ore slag, etc., which contain significant environmental pollutants.

What Cold Pressed Briquettes Can Do in Steel Production?

Cold pressed briquette plays different roles. It provides a lot of benefits in steel production such as mill scale recycling.

Coolant: In the steel smelting process, temperature control is crucial. Cold-pressed briquettes can work as a coolant to help regulate the furnace temperature, ensuring the stability and efficiency of the smelting process. By rationally using cold-pressed briquettes, enterprises can reduce their reliance on traditional cooling materials, thereby lowering production costs.

Fluxing Agent: Under high-temperature conditions, cold-pressed briquettes act as a fluxing agent, assisting in the removal of impurities from molten metal, thereby enhancing the purity and quality of steel. This function not only optimizes the smelting process but also reduces the burden on subsequent refining processes, further improving production efficiency.

Carbon Emission Reduction: The use of cold-pressed briquettes helps reduce carbon emissions in steel production. By converting waste materials such as iron-containing sludge and dust into reusable briquettes, enterprises can significantly reduce the consumption of primary resources while minimizing solid waste emissions, contributing to the green transformation and carbon neutrality goals of the steel industry.

Resource Recycling: Cold-pressed briquette technology recycles waste materials such as dust, scale, and iron-containing sludge generated during steel production, transforming them into high-value metallurgical raw materials. This not only addresses the challenges of solid waste disposal but also creates additional economic benefits for enterprises, achieving efficient resource recycling.

Cost Reduction: The production process of cold-pressed briquettes is simple, energy-efficient and requires no additional equipment or space, significantly reducing operational costs for enterprises. At the same time, by reducing dependence on high-cost raw materials, enterprises can further optimize their production cost structure and enhance market competitiveness.

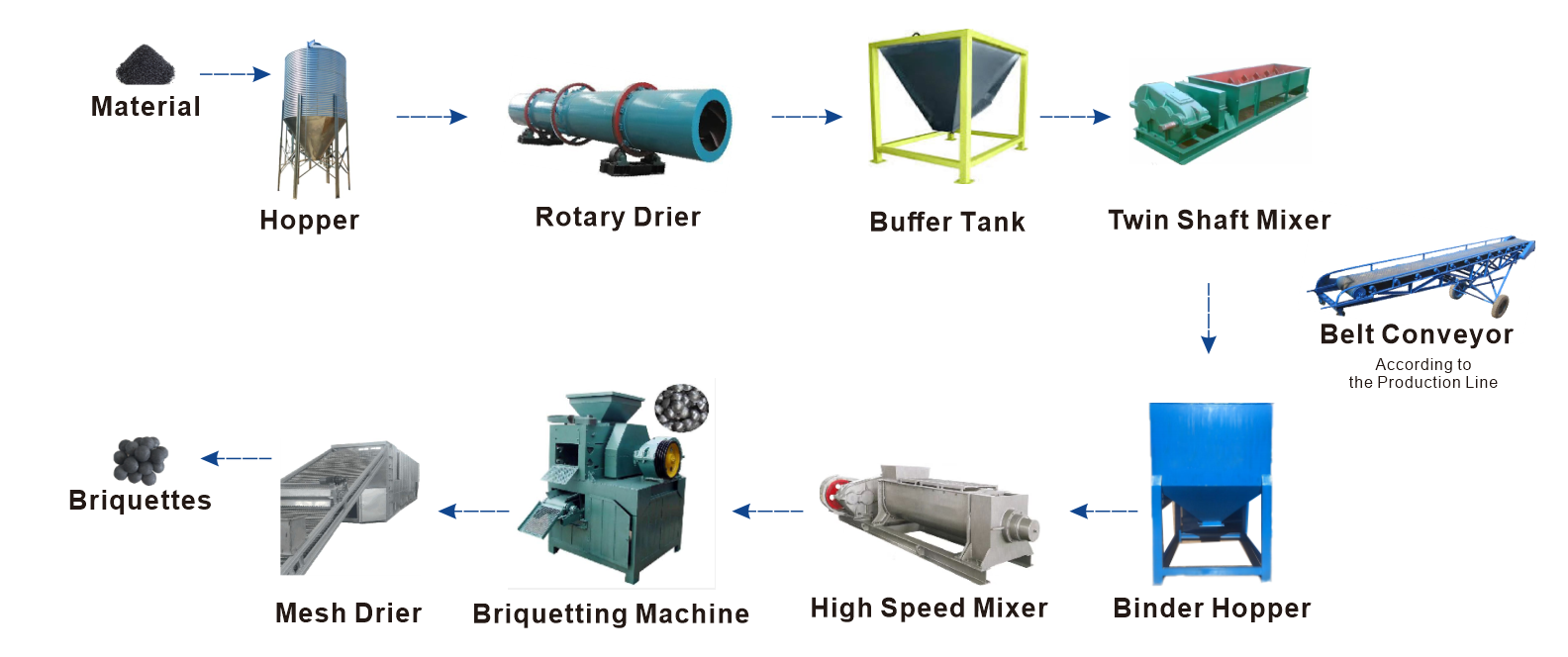

The Manufacturing Process of Cold Briquetting

Cold briquetting technology offers an effective method for recycling steel plant solid waste. By incorporating suitable binders, fine particulate waste is compacted into high-strength briquettess, enabling efficient recovery and reuse. Here are the steps of the manufacturing process of producing cold briquettes:

Raw Material Preparation

Prepare the raw materials used in cold briquetting, such as blast furnace dust, converter sludge, sintering dust, and mill scale. It's important to screen, drying, and proportion steel plant solid waste materials to ensure uniform composition.

Equipment involved:

Hopper: Used for raw material storage and delivery.

Hopper: Used for raw material storage and delivery.

Rotary Drier: Used for raw material drying.

Rotary Drier: Used for raw material drying.

Mixing and Blending

A precise amount of water, binder, and other additives is introduced to the raw materials. Through thorough mixing, all components are evenly distributed, enhancing the stability of the subsequent forming process.

Equipment Involved:

Twin Shaft Mixer: The twin shaft mixer is a widely used mixer in cold briquetting. It has two shafts that are horizontally placed and rotates toward different direction. Twin shaft mixer is applicable for coal processing, metallurgical powder processing and materials mixing. It is easy to maintain, stable, high efficient and energy saving.

Twin Shaft Mixer: The twin shaft mixer is a widely used mixer in cold briquetting. It has two shafts that are horizontally placed and rotates toward different direction. Twin shaft mixer is applicable for coal processing, metallurgical powder processing and materials mixing. It is easy to maintain, stable, high efficient and energy saving.

Binder Hopper: Used for feeding binder to the materials. When the binders are fed through the hopper into the machine, they are transported via the screw feeder directly into the high speed mixer, where the raw materials and binders are thoroughly mixed.

Binder Hopper: Used for feeding binder to the materials. When the binders are fed through the hopper into the machine, they are transported via the screw feeder directly into the high speed mixer, where the raw materials and binders are thoroughly mixed.

Forming Briquettes

Cold briquetting is compressing the well-blended materials and binders into briquettes in specific shapes and sizes (ball shape or brick shape).

Equipment Involved:

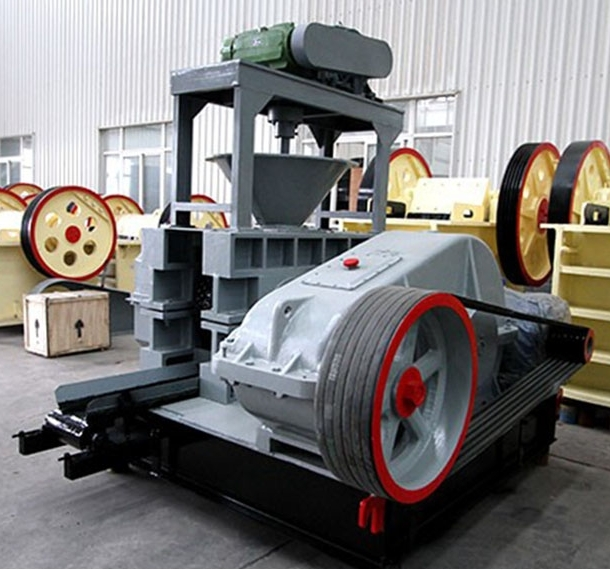

Briquetting Machine: Applicable Materials: Various metal ore powders and slags, including iron powder, sponge iron powder, manganese powder, aluminum powder, magnesium powder, metal silicon powder,chromium powder,etc.

Briquetting Machine: Applicable Materials: Various metal ore powders and slags, including iron powder, sponge iron powder, manganese powder, aluminum powder, magnesium powder, metal silicon powder,chromium powder,etc.

Hydraulic Briquetting Machine: Applicable Materials: Aluminum powder, iron powder, iron slag, oxide scale, charcoal powder, coal powder, coking coal, carbon powder, gypsum, kaolin, clay, activated carbon, tailings, slag, sludge, etc.

Hydraulic Briquetting Machine: Applicable Materials: Aluminum powder, iron powder, iron slag, oxide scale, charcoal powder, coal powder, coking coal, carbon powder, gypsum, kaolin, clay, activated carbon, tailings, slag, sludge, etc.

Drying and Curing

Freshly formed briquettes typically retain a high moisture content. They must be dried in dryers or air-dried (for example, customers can use air-dried binders) to remove excess moisture and enhance structural integrity.

Equipment Involved:

Mesh Drier: Use for finished briquettes to dry. The briquettes will be placed and dried on the mesh drier.

Mesh Drier: Use for finished briquettes to dry. The briquettes will be placed and dried on the mesh drier.

Storage and Application

Once dried completely, briquettes can be directly fed into blast furnaces or other equipment as a valuable resource for recycling.

The Role and Advantages of Jianjie Binder in Cold Briquetting

Jianjie binder for briquettes is specifically formulated and offers several key advantages:

Superior Bonding Performance

Jianjie binder significantly enhances qualification rates, ensuring structural stability during the cold-pressing process while minimizing cracks and breakage. Each ton of Jianjie binder can produce 25–35 tons of briquette with a qualification rate of 98%. The wet briquettes can remain intact after a 2-meter drop test, while the dried briquttes can achieve a strength of over 100kg. Finished briquettes show no situations like cracking, disintegration, or pulverization.

Help Remove Calcium Oxide (CaO)

Jianjie binder possesses patented technology for removing anti-calcium oxide in dedusting ash. The active calcium oxide present in the dedusting ash absorbs water and expands 1.5 to 2.5 times in volume, which can cause the briquettes to disintegrate and pulverize during the drying or air-drying process, leading to an excessively high pulverization rate. This binder contains anti-calcium oxide components that can effectively inhibit briquettes disintegration.

Enhancing Metallurgical Performance

Increasing Stability

Excellent Compatibility

Suitable for cold-pressing mixtures of 2–3 types of steel plant solid waste materials, including calcium oxide-containing converter dust, blast furnace dust, iron oxide scale, gas sludge, OG sludge, steel slag, and return fines.Strong Binding Force

Contains high-binding-force components, requiring minimal usage while delivering high adhesion. It ensures a high qualification rate and excellent cold strength, meeting the requirements for steelmaking recycling.

Environmentally Friendly and Non-Toxic

Composed of eco-friendly materials, Jianjie binder releases no harmful substances, ensuring safety for both the environment and workers.

Versatile Adaptability

Jianjie binder for briquettes is compatible with various types of steel plant solid waste materials, accommodating different compositions and particle sizes to meet diverse forming requirements.

Summary

The cold briquetting and recycling technology ensures that dust briquettes and formed coke have sufficient strength for reuse in furnaces, providing a direction for the resource utilization of dust and coke fines. This technology gradually transforms accumulated dust into valuable resources, not only staving energy and reducing production costs but also increasing output. It represents a sustainable direction in solid waste treatment and utilization technology, holding practical significance for achieving sustainable economic development and environmental protection.

Jianjie provides high-quality binders for briquettes, which significantly increase the qualification rate with a low dosage. Jianjie binders for briquettes are also applicable to various industries and materials, such as steelmaking, coal and coking, metal and mineral powder, etc.If you are interested in our service and product, please contact us via info@jianjiebinder.com. Looking forwarding to hearing from you!

Post time: Mar - 11 - 2025