)

Binder for Pellet of Pulverized Nonmetallic Ore

Related Content:

Binder For Briquette Of Phosphorus Ore Powder

Product Specification

Executive Standard: Q/HJSY 001-2022

Binder Technical Specification | |

Item | Value |

Appearance | Fluid powder |

Fineness: (-250μm) (%) | ≥90.0 |

Moisture Content (%) | ≤12.0 |

pH | 7.0-9.0 |

Bulk Density (g/L) | 1000±300 |

Viscosity (mPa·s) | ≥5 |

Phosphate ore powder binders are special binders for phosphate powder, and this innovative technology has been widely adopted by the phosphorus industry to recover phosphorus resources, improve the comprehensive utilization of resources, reduce energy consumption and save production costs.

In addition, these binders are better than traditional inorganic binders because they have high viscosity, low addition, strong bonding, high pellet forming rate, high cold and hot strength to meet the furnace charge requirements. This binders are used to produce pellets with high compressive strength and short pellet formation time. Through this process can reduce the emission of phosphorus slag and mud phosphorus in the process of yellow phosphorus production, improve the quality of yellow phosphorus products, economic and environmental protection, solve the problem of the use of phosphate powder and the shortage of mineral sources for yellow phosphorus production.

Product Characteristics

High Professionalism:

It is used in pellet of phosphorus ore powder to produce phosphor.

High Binding Strength:

High binding performance, high forming rate and high cold/hot strength. It can meet the requirements of electric arc furnace.

Ease of Use:

Mix binder and material well before stirring well with water, and then cold-press.

Cost Reduction:

Less binder for more products, high binding performance, high forming rate, high compression strength and low cost.

Good Effect:

Each ton of binder can produce 35-35 tons of pellets. High forming rate (98%). 2m-drop integrity (wet pellet). High cold strength (100 kg/pellet) and high hot strength (1000℃ burning; 100 kg/pellet).

Product Maintenance

Get Free Sample:

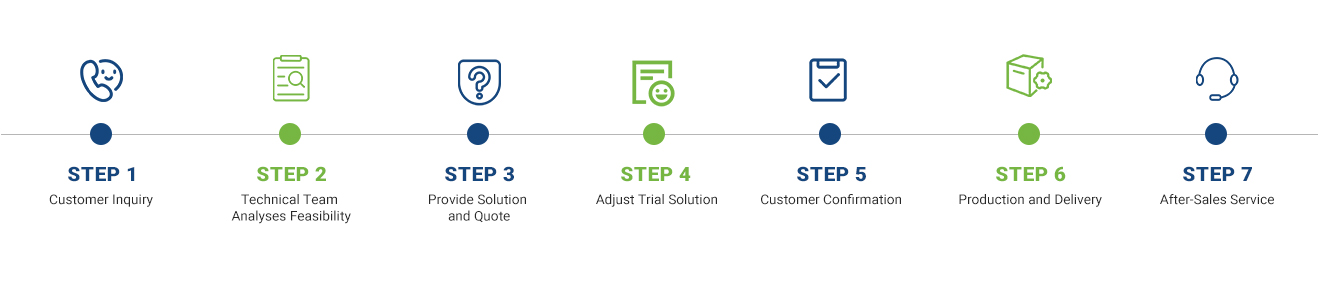

Service Process

Our Services

)

We specialize in delivering comprehensive, customized solutions tailored to our clients' unique requirements. Our services encompass production line design, equipment upgrades, and product parameter adjustments based on trial results, ensuring optimal performance and feasibility. Our team consists of experts with deep theoretical knowledge and extensive practical experience in binder engineering R&D, design, manufacturing, and technical support. We offer a full range of services, including technical consultation, scheme design, product fabrication, equipment sourcing, installation and commissioning, binder supply, production operations, and dedicated after-sales support. Additionally, we provide turnkey EPC (Engineering, Procurement, and Construction) services or phased EPC solutions, customized to meet our clients' specific requirements.

Our Factory

)

Jianjie Group invested 20 million USD to build a new composite material production base and an automated production line in Dazhou, Sichuan Province. The facility covers an area of more than 13,300 square meters and employs nearly 200 people. We have been focusing on the binder industry for 15 years, and our products are exported to more than 20 countries. With an annual production capacity of up to 300,000 MT, our production scale is among the top in the same industry in China. Our main products include iron ore organic binder, RHF dezincification de-dusting ash binder, dedusting ash briquettes binder, metallurgical furnace binder, drilling fluid filter loss reduction agent, coke powder binder, air-dried briquettes binder, carbon additive binder, and pre-gelatinized maize starch, among others.

FAQ

Products

Our products have strong viscosity, high Qualification rate & anti-calcium properties, and are also environmentally friendly & cost-effective.

Yes, we can. Our binder can increase strength and viscosity. Customized products are also available according to your requirements.

One year.

Transportation

The production time normally takes 3-5 working days. Delivery time usually takes 30-45 days by sea to your port.

Our terms of delivery are EXW, FOB , CFR, and CIF.

25KG per plastic woven bag or 1000KG per jumbo bag.

)

)

)